What is the sports wear fabric

sports wear fabric is the fabric used for sports wear, which is wore when people take exercise, go for a run, poly a sport etc. owing to the sports wear is used in the particular time to perform a particular task, the fabric is different from the normal clothes fabric. So, the sports wear fabric is always stretchable, breathable, very nice hand feeling and so on.

we concluded 10 factors to choose these fabrics, after take large business with sports wear manufacturers.

factors need consider

- The material

- Spandex (some called Lycra, we have a blog on this theme. Please check)

Spandex fiber is widely used in all kinds of sports wear to make the fitness better, because this fiber has the best stretchability. It can stretch 100 times more than its original size.

Most of the fiber in the nature has no or little stretchability, so when producing the sports wear, the factory will combine some fiber with spandex fiber to make the sports wear has more stretchability to over come fitness problem. The composition is 2%-30% in normal based on different stretchability request.

- The Cotton

Cotton fabric is a very good nature fiber, so it is known as a health and comfortable. Now many sports wear producer produce with fabric in cotton and spandex fabric. But the cotton does not absorb sweat, so the cotton fabric always does not used in the vigorous exercise. Otherwise, the producers need add much chemical wicking addictive.

- The Nylon (Polyamide)

Nylon fiber is the first synthetic fiber in the world developed by USA, it is one of the most important things in the synthetic fiber industry.

The nylon fiber has many good virtues:

The abrasion resistance is better than many similar fibers, so the fabric durability is also better.

Nylon fabric has good moisture absorption, so the clothes made from nylon are more comfortable to wear than polyester clothes.

Nylon fabric is regarded as a light fabric, so it is suitable to produce the sports wear fabric, swimwear fabric, yoga wear fabric, outwear fabric and so on.

Nylon fiber has excellent elasticity and elastic recovery. When combined with spandex fiber, the performance will be better.

Nylon fiber is good in shiny and matt. No matter customers prefer shinier or matter, they can find the best in nylon fabric. So, the luxury dancer wear(shiny) and the stretchable lady wear (matt) are always produced in nylon.

But the nylon fiber has a worse heat resistance and light resistance, so it requests higher technique in producing, especially in the setting and finishing process.

Nylon has a bit higher price and it is always used in some high-quality needed clothes.

▲nylon spandex made sports wear fabric

- The Polyester

Polyester is the most widely used fiber in the fabric in this time. This fiber is most similar to the nylon and the cost is much cheaper and easy to produce.

Similar to the nylon fiber, the polyester also has good performance in abrasion resistance, moisture absorption, elasticity and elastic recovery. Most time, polyester is a good replacement of nylon.

Polyester fabric has good chemical resistance, the bright color can stay for a long time. it has a smooth hand feeling, stiff and elastic, anti-folding and shrinking, easy to wash and dry, and not easy for corrosion.

The polyester fabric is easy to undertake a higher temperature and the fabric will be stable after finishing.

Now the polyester spandex sports wear is all the rage all over the world.

- The Bamboo Fiber

Bamboo fiber is a cellulose fiber extracted from natural bamboo. The raw bamboo fiber has the characteristics of good air permeability, instant water absorption, strong abrasion resistance and good dyeability. It has natural antibacterial, antibacterial, anti-mite, deodorant and anti-ultraviolet functions.

So if you attach much importance on the nature and do not like the synthetic fiber. Bamboo Fiber is a good choice to replace cotton.

- Structure technique

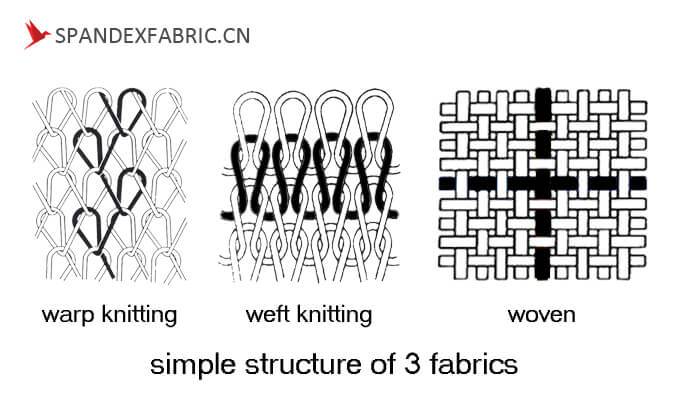

the sports wear fabric normally has woven and knitting.

The woven fabrics are made up of looms in the form of picking by interlacing the warp and weft directions. and their weaves generally include plain weave, twill weave and satin weave and their changes. This kind of fabric is firm, stiff and not easily deformed due to the interlacing of warp and weft, but less stretchy. So it is always produced as accessories.

▲warp knit weft knit woven structure

Knitting is a process of inter-looping of yarns or inter-meshing of loops. Its properties are distinct from woven fabric in that it is more flexible and can be more readily constructed into smaller pieces.

There are two basic varieties of knit fabric: warp knitting and weft knitting (circular knitting). Warp knitting is a family of knitting methods in which the yarn zigzags along the length of the fabric, i.e., following adjacent columns, or wales, of knitting, rather than a single row, or course. For comparison, knitting across the width of the fabric is called weft knitting.

The knitted fabric is good in stretchy, especially with fiber spandex. the structure is various and production capacity is big, it contributes to be the king of sports wear with so many advantages.

- Stretch

Stretch is believed to be one of the most important elements for choosing the sports wear. As talked just now, structure is a point to influence the stretch. Besides, the spandex composition is the biggest point, because the spandex has perfect stretch. The sports wear fabric normally has spandex composition from 2% to 30%. The higher composition is certainly will make the fabric have better stretch. Thirdly, the addictive like softener and silicone oil put when setting and finishing will also help to make good stretch.

- The color or print

One color sports wear will give feeling of simplicity, grandeur etc;

The mix color spots wear will give feeling of youth, vigor;

The print sports wear will give feeling of creative and cool personality.

For the factory all the color are available to produce, you only need provide a pantone color number or provide a color sample, then we can produce same color to you.

What important is the colorfastness. Colorfastness is the resistance ability of a fabric color to change in its color. The sports wear is always rubbing and washing many times, so the colorfastness need a high quality, recommend not less than grade 4 ( total grade 1-5, the high number means high quality).

The print, normally is the rotary print. It is a complicated process in printing: the workers make the pattern design on the rotary in different color and the print will be finished by add all the rotary color. After rotary print, the fabric need washing and setting again.

▲the roatary print

Now there is an easier choice. It is used in polyester spandex sports wear fabric, while nylon spandex sports wear fabric is not good. It is sublimation print, also called paper print. Compared to the rotary print, the machine will not print on the paper instead on the fabric directly. Then the machine will transfer the print from paper to fabric in high temperature. Sublimation is a good method to keep the fabric plain and high quality, decrease bad products and increase produce capacity.

Now with the development of computer design, the computer can help to make design on the paper, the sublimation print is widely used in small quantity produce to lease the creative and cool personality.

- Abrasion resistance

the sports wear always rub when using it, so the abrasion resistance is important when you choose the fabric. The higher abrasion resistance will ensure the sports wear have the long life. As we talked above, the polyester and nylon have a good abrasion resistance and good to choose as sports wear fabric.

If you prefer the other material, we recommend to produce a high weight to keep the fabric a bit thicker.

- Functional- warm keep and breathable / dry fit

if you take excise in low temperature and need keep warm; if you do not take the strenuous exercise and has little sweater, then warm keep is important to you. Cotton spandex sports wear fabric is good for you, because cotton has good performance in warm keep.

Nowadays, some synthetic has the warm keep function. That fiber bundle device composed of semi-permeable hollow tubes with a certain size of aperture and a molecular sieve function. The cross-sectional structure reduces the weight of the fiber by 20%. At the same time, the fiber contains a large amount of static air, which makes the fabric warmer than ordinary the homogeneous fabric has increased by 65%.

The breathable function is more demand. Most of our customers need breathable in fabric when produce the running wear, yoga wear, out wear etc. breathable will help the sporter eliminate the sweater and keep warm.

Normally, at present, we improve the dry fit function by add the chemical addictive when finishing. With the help of addictive, the water can infiltrate to the fabric fast.

There are some fibers add the dry fit function when fiber produce. If use the functional fiber, then we can reach same goals.

▲the breathable sports wear fabric

- Functional- anti-bacterial

Anti-bacterial fabric has good safety. It can effectively and completely remove bacteria, fungi and mold on the fabric, keep the fabric clean, and prevent the regeneration and reproduction of bacteria.

In general, the anti-bacterial function is not an accurate expression. We need point out what bacterial need to prevent, due to different bacterial has different chemical addictive, like staphylococcus aureus, escherichia coli, methicillin-resistant staphylococcus aureus MRSA, klebsiella pneumoniae, fungi include candida albicans, and molds include aspergillus niger, globosum chaetomium, aureobasidium pullulans, etc.

Now the anti-bacterial chemical addictive is very good in producing and the performance keep improved: still good performance after 50+ washes.

- Functional- waterproof

The waterproof sports wear fabric will not be wet inside or outside after water or rain touched. If there leave some water stains when the water goes down, we just need wipe it.

However, the waterproof fabric is not advantageous to sweat evaporation, so these fabrics is normally use in some particular sports wear, which is always use in water sports. Sometimes, the fabrics are also coated and produced to some leather sports wear. The waterproof fabric also used in all kinds of cover-chair cover, table cover, car cover etc.

the waterproof sports wear fabric is same to the normal one, just add the chemical addictive in finishing process.

The ISO waterproof grade is 0-5, the higher number, the better waterproof performance.

- Function-anti-UV

it has been much valued by more and more consumers to prevent ultraviolet rays from harming the human body. On one hand, the ultraviolet rays from the solar spectrum makes the textiles fade and embrittle, on the other hand it causes human skin aging, leading melanin and stains. More serious, it can induce cancer and endanger human health.

So many sports fabric used outside request anti-UV protect.

By add the anti-UV addictive in finishing process, the fabric can have the special function. Meanwhile it is non-toxic, safe to human body, non-irritating to the skin, no allergic reaction, and does not affect the color, strength and moisture permeability of the fabric.

According to the AS/NZS4399:1996, the test grade of anti-UV is

| UPF | Performance | UV transmittance (%) | UPF grade |

| 15-24 | Medium | 6.7-4.2 | 15, 20 |

| 25-39 | Good | 4.1-2.6 | 25, 30, 35 |

| 40-50, 50+ | Excellent | ≤2.5 | 40, 45, 50, 50+ |

In general, the customer request UPF 30+ or UPF 50+

- Recycled PET Fabric

The recycled fabric has gotten pretty popular in recent years. The recycled fabric is mainly regard as recycled polyester fabric. Although there is recycled nylon and other recycled fiber in the market, but still only has small quantity.

The bottle environmental protected fabric, the RPET fabric, recycled polyester fabric, recycled PET fabric is named in same. The fiber of this fabric is extracted from discarded mineral water bottles and Coke bottles. This fabric is new green product with environment-friendly, low carbon, oil resources saving. It is popular, especially in developed countries, for the idea of waste utilization.

Now we sell the Recycled fabric with GRS certificate and TC certificate to ensure our fabric is true recycled fabric certified by third party.

With laying more emphasis on the environment protection, the recycled PET fabric will have bigger demand in future.

▲GRS certificate